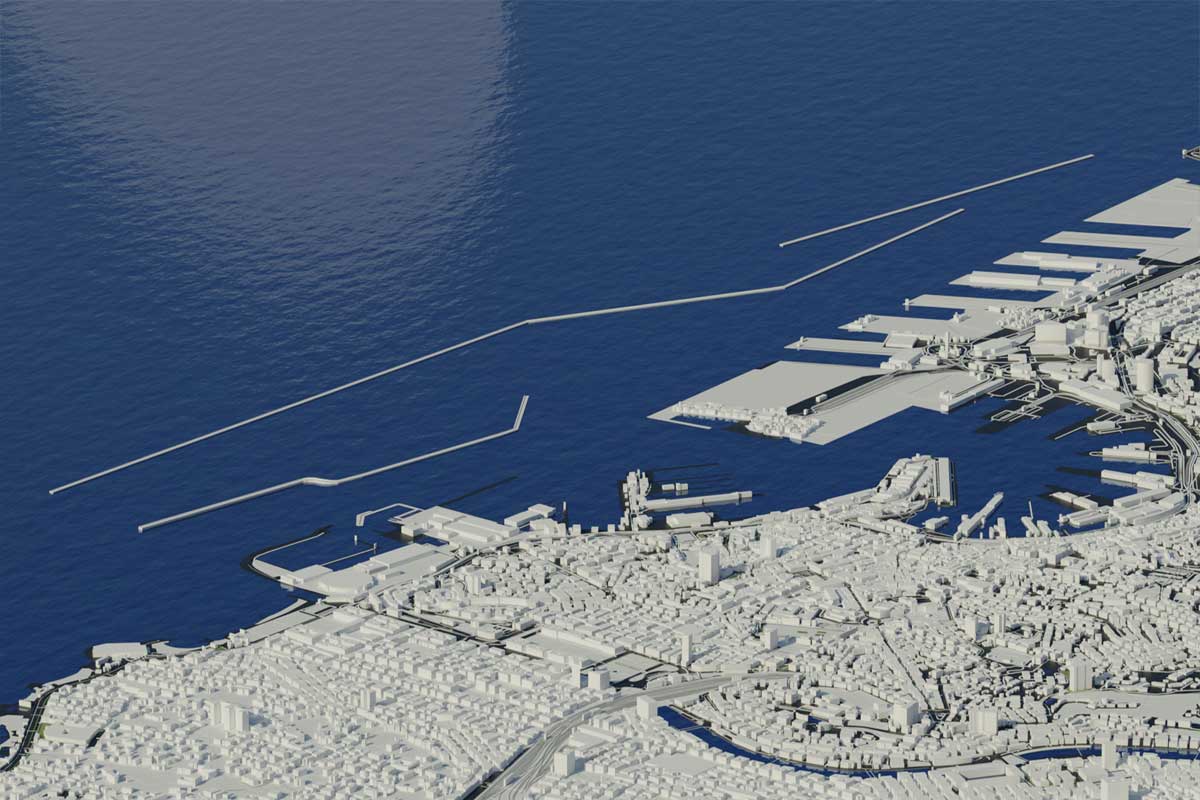

The work has a volume of 1030 m; 950 of which have been realized by means of cellular cassions and the remaining ones by means of a cofferdam driving .

Near the end of the protection dock of the Calafati Basin and the front side of the Montano Shipyards that are located on a very low depth, the connection with the New Pier Italia was performed by means of metallic cofferdam on both sides and a ramp connecting the store yard of the New Pier (elevation +2.5 m) to the country floor (~ +2.0) of the Montano Shipyards.

The runways are supported directly put on the docks’ cassions while the internal rail’s runway was made by means of concrete beam and foundation piles with a big diameter.

For the ships’ docking and berth some rubber fenders and cast iron mooring bitts were used.

The embankment under the store yards was made with a mix of quarry up to +0.50 m.

The flooring of the store yards was made with a bituminous conglomerate and a foundation layer of granulated mix.

The work has a volume of 1030 m; 950 of which have been realized by means of cellular cassions and the remaining ones by means of a cofferdam driving .

Near the end of the protection dock of the Calafati Basin and the front side of the Montano Shipyards that are located on a very low depth, the connection with the New Pier Italia was performed by means of metallic cofferdam on both sides and a ramp connecting the store yard of the New Pier (elevation +2.5 m) to the country floor (~ +2.0) of the Montano Shipyards.

The runways are supported directly put on the docks’ cassions while the internal rail’s runway was made by means of concrete beam and foundation piles with a big diameter.

For the ships’ docking and berth some rubber fenders and cast iron mooring bitts were used.

The embankment under the store yards was made with a mix of quarry up to +0.50 m.

The flooring of the store yards was made with a bituminous conglomerate and a foundation layer of granulated mix.